Rail manufacturing involves making and assembling ‘rolling stock’ – locomotives, passenger cars, freight wagons, trams, light rail and their related components and systems.

We used to manufacture a lot of rolling stock here in Australia. But over the past few decades we’ve relied heavily on imported products. Between 2013 and 2023 we exported about $50 million of rolling stock and components while importing around $1.1 billion worth (IBISWorld 2022).

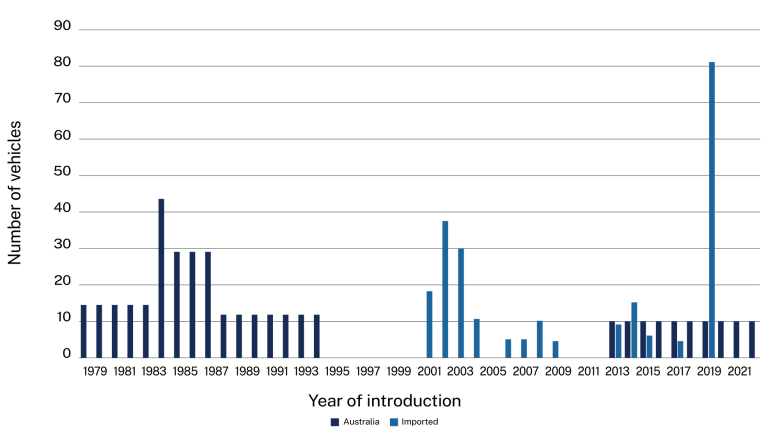

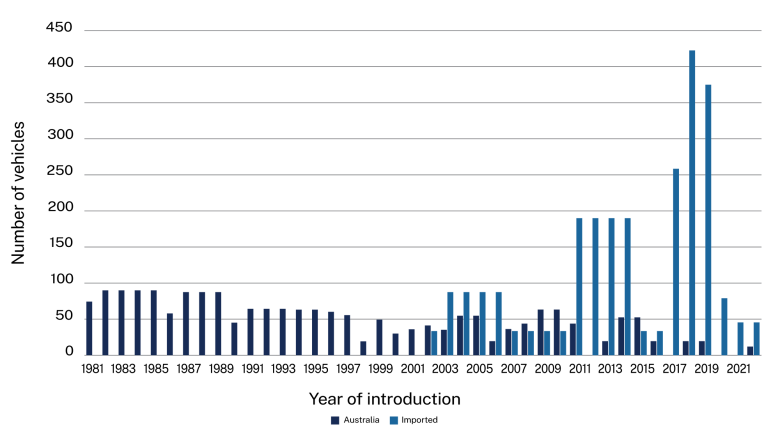

The charts below shows where the vehicles in Australia’s light and urban heavy rail fleets have been manufactured over time.

About this data:

- Numbers for each year represent rolling stock that are still in service, rather than the total introduced each year

- Vehicles for some rolling stock were introduced over a wide timeframe. Where this occurs we have used an average of vehicles introduced by year.

- These charts exclude the Victorian W class trams introduced in the 1950s.

Country of origin of Australia's urban heavy rail fleet

This shift to offshore manufacturing is partly due to tariff reforms and trade liberalisation over the last 40 years, which has seen large multinational companies dominating the rail manufacturing sector (Engineers Australia 2022).

Another reason is ‘vertically separated’ rail operations, where the manager of a rail network sells track access to a private train operator, which sets its own standards. As a result, Australia has many small markets for rolling stock, each with different standards. That makes it hard for local manufacturers to be competitive when they have to meet so many different requirements.

Despite our recent reliance on imports, we still have the capabilities to manufacture world-class rolling stock and components here in Australia.

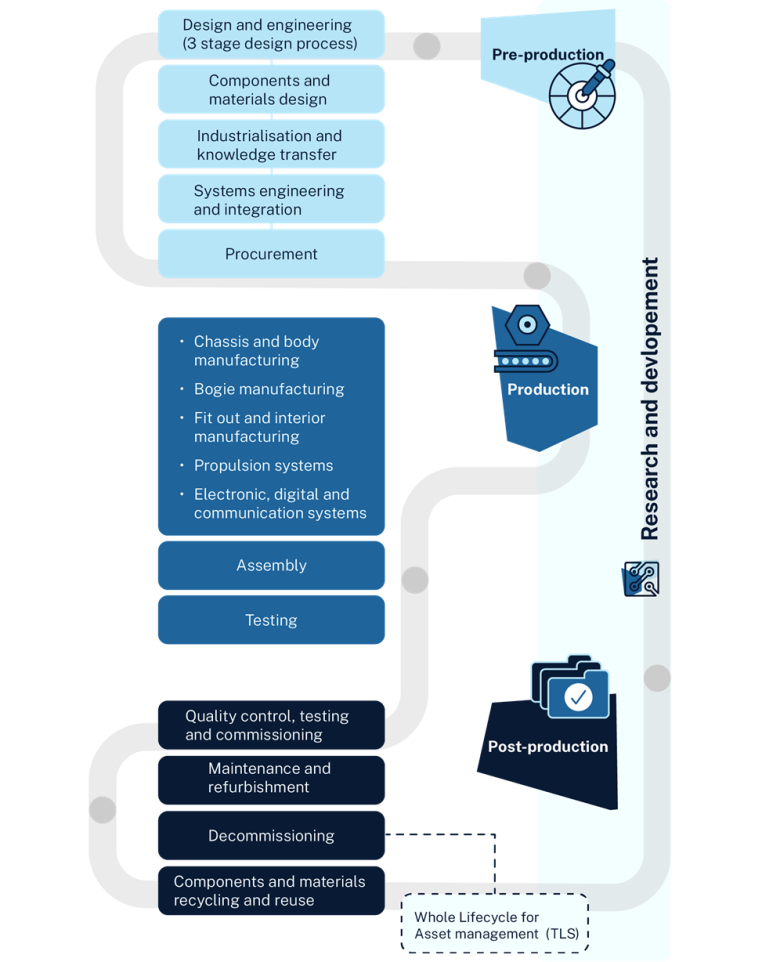

The rail manufacturing lifecycle

This graphic shows the manufacturing lifecycle of rolling stock, all the way from initial design to decommissioning and recycling.

Our rail manufacturing capabilities

Australia’s rail manufacturing industry focuses on 3 main capabilities:

- components (part of the pre-production stage)

- assembly (part of the production stage)

- maintenance and repair (part of the post-production stage).

Components

Australia has a well-developed industry for making rolling stock components. We have many small companies manufacturing technically complex components and systems that meet Australia’s high safety standards.

The components and systems we make in Australia are internationally proven. But in most cases, we need to modify them for Australian conditions and networks. That can make it hard for Australian manufacturers to sell their products to other countries.

Assembly

Assembly means putting components together to create rolling stock.

Our rail manufacturing sector is transitioning from a model where one manufacturer handles all aspects of rolling stock production from design to assembly.

Under this model, specialised small manufacturers can remain viable in the sector by supplying complex components and services to large manufacturers. These larger companies then import less complex prefabricated rolling stock from overseas before assembling and fitting them out in Australia.

Maintenance and repair

Transport networks need their rolling stock to be reliable, long-lasting, affordable to maintain, and fitted with the latest components and technology.

Australia’s world-leading maintenance and repair sector helps them achieve this with innovative methods like:

- real-time train monitoring and data analysis

- workshop automation and robot-assisted repairs

- simulation and modelling to reduce expensive manual testing

- complex sensors and diagnostics to detect defects

- software to optimise fuel consumption.